Hydraunautic designs and produces onboard hydraulic systems tailored to the most specific needs of professional boating.

Each project is conceived down to the smallest detail to ensure performance, reliability, and perfect integration into your vessel.

Our strength lies in our complete control of the process, from the initial drawings to the final installation on board.

This integrated approach allows us to offer highly customized solutions, that meet the highest quality standards in the maritime industry.

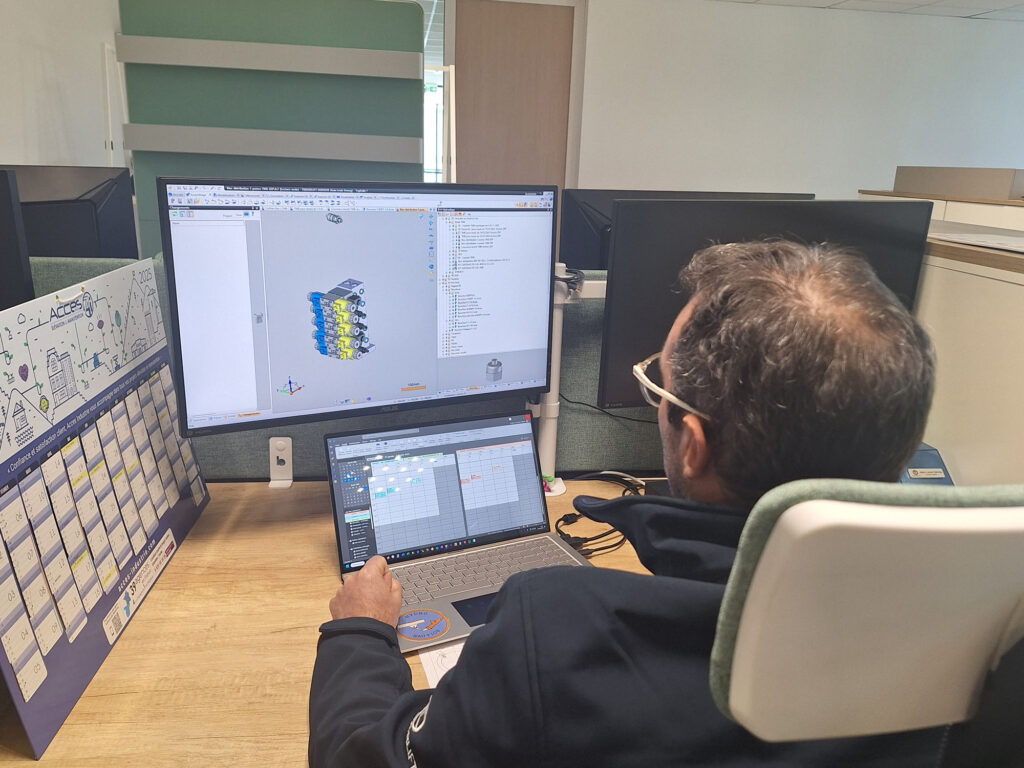

Hydraulic Architecture

Hydraunautic engineers design the vessel’s entire hydraulic architecture:

- definition of functional diagrams,

- sizing of the circuits,

- selection of components and control interfaces.

Each system is developed in harmony with the boat’s structure, ensuring smooth and long-lasting integration.

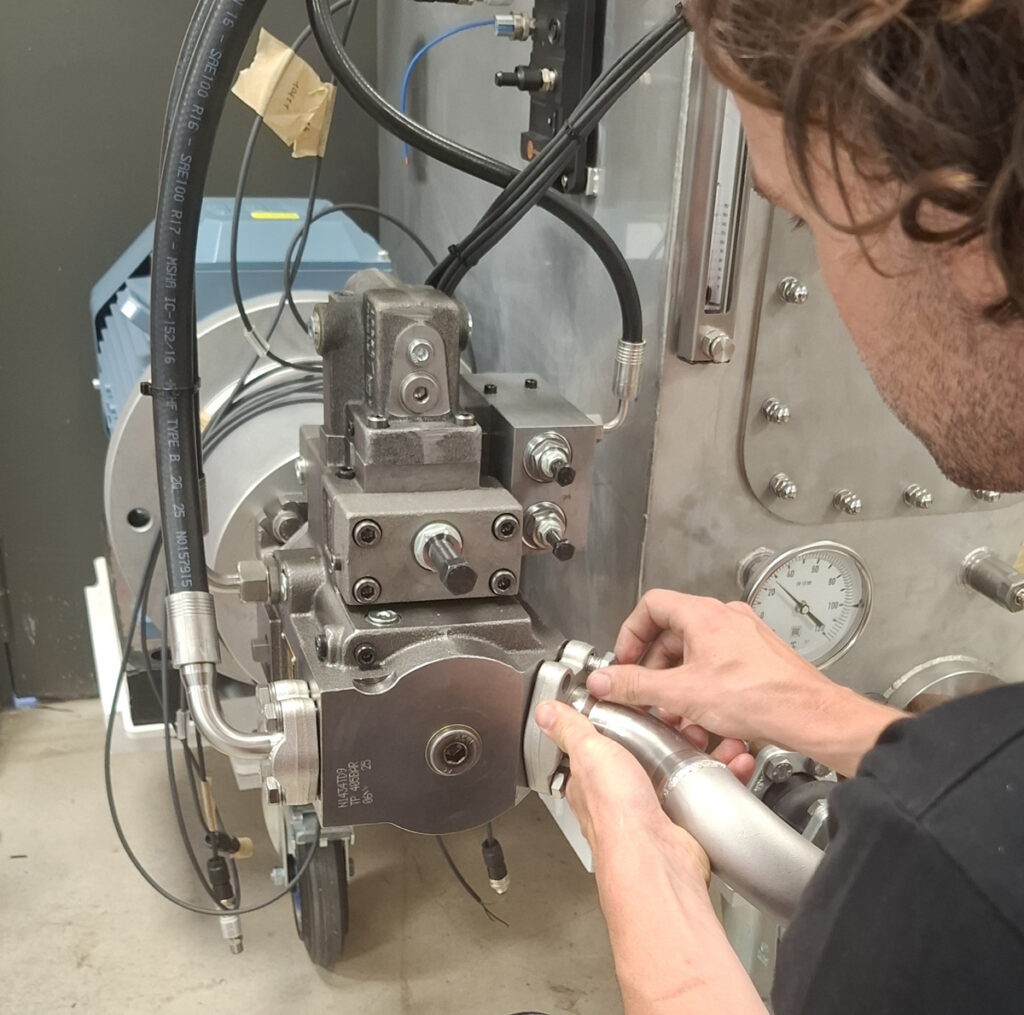

Custom Manufacturing

Hydraunautic carries out the in-house manufacturing of its hydraulic systems, including welding and shaping of the tanks.

This full control over production makes it possible to meet all technical and dimensional constraints, while ensuring consistent quality and complete traceability.

Strict component selection

We work with trusted suppliers specialized in marine environments, to ensure the reliability and durability of every hydraulic system.

Each component is selected for its performance, compatibility, and resistance to extreme marine conditions.

Assembly and clean-room installation

All Hydraunautic systems are assembled and installed in a clean room under controlled conditions.

This strict requirement ensures impeccable cleanliness of the hydraulic circuit and contributes to the operational longevity of onboard installations.

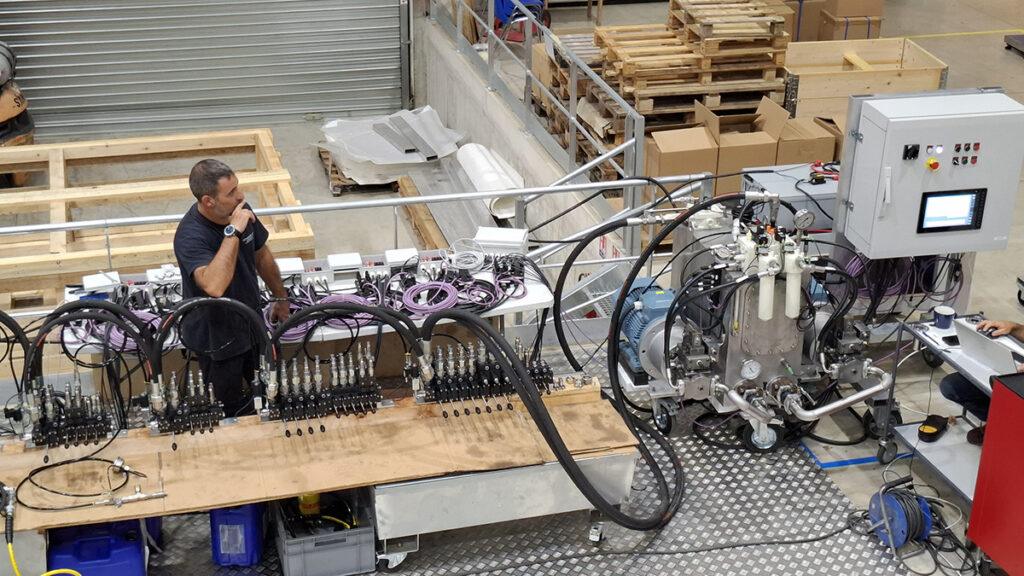

Product Testing before Shipment

Each system is factory-tested, reproducing the use cases defined in the specifications. This step is essential to ensure our clients benefit from the fastest and smoothest possible installation once on site.